PRO FLEX INDUSTRIAL SYSTEM

175 to 1000 kW

LARGE PELLET SYSTEM

The PRO FLEX offers highly economical and futureproof heating convenience using pellets. Their modular design enables these systems to be offered with an output range of up to 1000 kW, and makes them suitable for a wide variety of applications.

Benefits

Highly efficient combustion

Fuel is gasified with a staged supply of primary air under ideal ember bed temperature conditions. The amount of combustion air and fuel charge is regulated by means of a lambda probe, so that the system achieves an optimum level of efficiency. The released combustion gases are cleanly converted into thermal energy by mixing them with secondary air in a large rotating combustion zone at a temperature of around 1300 °C. The well proven cupola design enables a perfect burnout and long dwell times.

HIGHEST OPERATIONAL RELIABILITY

Operational reliability is greatly improved by the multi-stage modular design, particularly where several larger buildings need to be heated. Should one of the boilers connected in series fail, the remaining boilers simply continue to operate. This protects against total failure, which is of particular importance to municipal or commercial users.

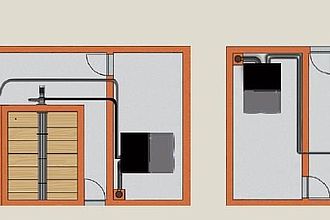

Modular design

Every section of the PRO industrial system can be handled by means of a pallet truck. Its assembly is perfectly straightforward. There are no long-winded assembly and installation steps to take.

STRAIGHTFORWARD OPERATION

Operating the PRO industrial system is especially easy thanks to the well thought-out and user friendly touchscreen interface. All settings and scans of system data can be made in just a few steps.

Flexible application options

Apart from their safety and economy, PRO systems offer further advantages, such as their flexible discharge solutions and the option of heating with pellets and woodchips.

Highest level

of convenience

It's all a matter of technology

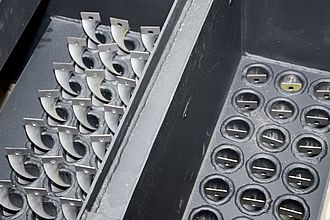

Industrial step grate technology

Self-cleaning step grates allow users to set the ember bed height and boiler output subject to demand and relevant fuel, without risking slag forming inside the boiler. The moving step grate keeps the primary air slots clean, ensures optimum combustion and also that ash is correctly discharged.

Self-cleaning heat exchanger

In cleaning mode, the turbulators inside the vertically arranged tube bundle heat exchangers move up and down. This prevents deposits that reduce efficiency and safeguards consistently low flue gas losses. This feature also ensures that the boilers can operate for exceptionally long periods without requiring servicing or cleaning. All critical zones inside the boiler are cleaned automatically

Highest operational reliability

Two discharge screw conveyors operating independently of each other guarantee the redundant and reliable pellet discharge from the storage room. Precise dosing, in conjunction with a specially developed industrial vacuum turbine, ensures totally reliable transportation into the 500 litre cyclone hopper. Pellets enter the combustion chamber via a pellet sluice that completely prevents any back burning or back smouldering.

FLEX

Guntamatic Flex discharge units are suitable for particularly large, intensively used, storage facilities.

The discharge screw conveyor of the vacuum discharge system has been designed for efficiency and a long service life. It offers a highly reliable operation as well as low cleaning effort,

and discharge from stores with sloping floors. Where the sloping floors are made on site, this is also a particularly affordable solution.

SAFELY HEATING WITH ECONOMY

- Ecologically sound and highly efficient: up to 94 % efficiency

- Industrial step grate technology for regulated ember bed temperature

- Extremely large self-cleaning heat exchanger in proven cupola design

- Long operating cycles without service or cleaning

- Modular design for the highest operational reliability

- Standard industrial product for quick availability

- Possible on-site installation by heating engineers

- Clever safety concept with protection against back burning and temperature monitoring of the fuel store

- Excellent quality and components tested several times

- First class spare parts service from our own production

- Large LED operating display

- Straightforward operation thanks to user-centred touchscreen interface design

- External access via PC or mobile (option)

- Automatic ash discharge with moveable ash box or fully automatic vacuum ash discharge into a 200 litre drum (option)

- Modular construction for easy handling and installation

- First class spare parts supply resulting from series production in house

- Fault menu and separate component tests make analysis and service easier

- Optimum accessibility for service and maintenance

Specification

Tabelle zum scrollen

Tabelle zum scrollen

Type PRO 175 | Set PRO 350 | Set PRO 600 | Set PRO 850 | ||

Fuel | Woodchips P16B or P45A* (EN14961-4) | ||||

Boiler output PRO 175 | 188 | The total output results from the respective combination of individual modules | kW | ||

Required chimney draught | 0.1 | 0.1 | 0.1 | 0.1 | mbar |

Water content | 572 | 1144 | 1716 | 2288 | Litre |

Ash capacity | max. 240 | max. 480 | max. 720 | max. 960 | Litre |

System width | 1700 | 2 x 1700 | 3 x 1700 | 4 x 1700 | mm |

Total weight | approx. 2200 | approx. 4400 | approx. 6600 | approx. 8800 | kg |

Safety heat exchanger | yes | yes | yes | yes |

|

Power supply | 400 V / 20 A | 400 V / 20 A | 400 V / 20 A | 400 V / 20 A |

|

* Combustion of P45A (G50) woodchips only in the case of excellent woodchip quality<br/> ** Rated output applies to modules with < 400 kW <br/> *** Maximum possible boiler output; model not available in Germany

Test report

Summary of test assessments:

"especially straightforward and convenient layout thanks to a unique modular design; multi-stage modular construction also ensures highest operational reliability and protects against total system downtime; highly flexible discharge and fuel selection; ..."

- Tested in 2012 and 2013 for cleanest combustion and particularly high efficiency to EN 303-5 by the BLT Wieselburg

- Tested for mechanical robustness (under pressure) by the TÜV SÜD SZA

- Tested for fire safety by the IBS Linz

- Tested in accordance with the strict requirements of the European Machine and Plant Safety (CE)

- Tested for electrical safety by Ziviltechnik Stöp

- Assessment of risk analysis and CE certification by HET engineers

Awarded the Austrian Innovation Prize 2014

Awarded the Austrian Environmental seal ZU 37