POWERCHIP

UP TO 400 KW

WOODCHIP HEATING SYSTEM WITH STEP GRATE TECHNOLOGY

Our Powerchip heating systems, with step grate technology, effectively combine maximum economy and minimum emissions. Subject to approval and model, these boilers can also be converted to alternative fuels, such as pellets, miscanthus and plant matter.

Benefits

Highly efficient combustion

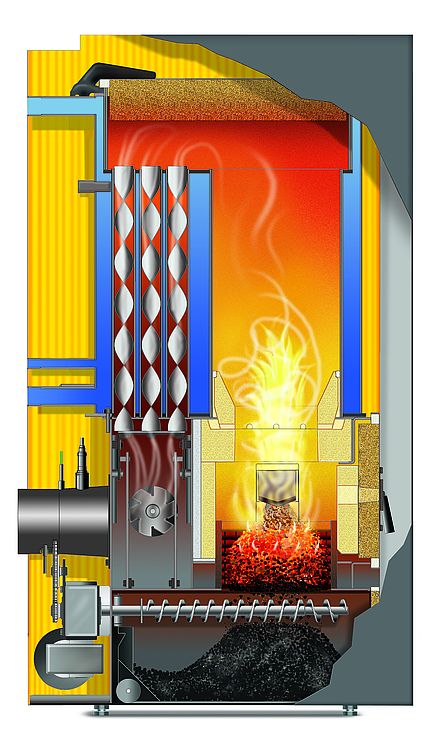

The woodchips are gasified on the step grate, where primary air is supplied, at an ember bed temperature of around 850 °C. The amount of combustion air and fuel charge is regulated by means of a lambda probe, so that the system achieves a level of efficiency of up to 94 %. With the aid of secondary air, the generated combustion gases are cleanly and efficiently converted into energy in a large rotating combustion zone.

low power consumption

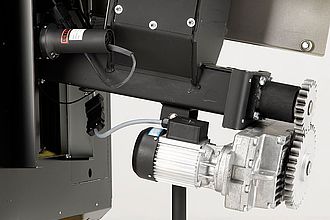

The pioneering discharge system operates with slow turning motors that consume very little power and develop extremely high torque of up to 1200 Nm. In addition, the progressive screw conveyor incline and the optimised trough geometry ensure the highest operational reliability.

Advanced touchscreen controller

Operating POWERCHIP heating systems is particularly easy thanks to the well thought-out and user friendly touchscreen interface. All settings and scans of system data can be made in just a few steps.

HIGHEST CLEANING CONVENIENCE

An ash screw conveyor transports the ash from the self-cleaning step grate into an especially large moveable ash box. Dust from the automatic heat exchanger cleaning process is also continuously moved into a separate, easy-to-empty container. The optional automatic vacuum ash discharge into a 200 litre drum is highly convenient.

Durable quality

In order to ensure that our appliances meet our high quality aspirations and those of our demanding customers, we manufacture them completely and exclusively using the best possible materials in our ultra-modern Austrian factory.

Highest level

of convenience

It's all a matter of technology

Industrial step grate technology

POWERCHIP systems operate with a self-cleaning step grate which is generally only found in larger plants. This enables the ember bed height and boiler output to be adjusted in line with demand and fuel, without risking slag forming inside the boiler. The moving step grate keeps the primary air slots clean, ensures optimum combustion and also that ash is correctly discharged.

High grade components

In order to prevent unpleasant surprises, POWERCHIP boilers are made exclusively using the highest grade components. The robust version of the agitator motors and screw conveyor discharge, the reliable motors and gear units and the resilient silicon combustion chamber with step grate technology are but a few examples of this.

Control app

The optional pioneering control app from Guntamatic lets you regulate your heating system at any time and from anywhere. The intuitive user prompts and the touch/swipe controls allow you to call up and adjust temperatures and heating programs with a smartphone. Furthermore, the app keeps you informed of the current status of your heating system and offers various forms of analysis.

AUTOMATICALLY HEATING WITH ECONOMY

- Self-cleaning industrial step grate for adjusting the ember bed size and boiler output without generating slag

- Clean primary air slots and optimum combustion through moving step grate technology

- Up to 94 % efficiency

- Self-cleaning tube bundle heat exchanger ensures long operating times without maintenance or cleaning measures

- Suitable woodchips (G30 and G50, up to W30); miscanthus and plant-based fuels with optional stainless steel insert

- Ash screw conveyor and moveable ash box or fully automatic vacuum ash discharge into a 200 litre drum (option) for the highest cleaning convenience

- Well thought-out and user friendly interface with touchscreen

- Control by mobile (option)

- High grade components for maximum operational reliability

- Excellent quality and components tested several times

- First class spare parts service from our own production

- Secure cascade operation prevents total downtime

- Modular pellet discharge concept, suitable for almost every situation

- Minimum power consumption thanks to energy efficient discharge

- Extremely robust pellet discharge screw conveyor with sprung arm agitator

Specification

Tabelle zum scrollen

Tabelle zum scrollen

TYPE | POWERCHIP 40/50 | POWERCHIP 75 | POWERCHIP 100 |

|

|---|---|---|---|---|

| Up to four individual boilers can be linked to form a single cascade. |

| ||

Fuel

| Woodchips P16B or P45A* (EN14961-4) |

| ||

Boiler output

| Woodchips 14,5 - 49 | Woodchips 22,5 - 75 | Woodchips 26,9 - 99/101 (85***) | kW |

Required chimney draught | 0.15 | 0.15 | 0.15 | mbar |

Water content | 147 | 256 | 256 | Litre |

Ash box – "grate" | 60 | 80 | 80 | Litre |

System width | 1574 | 1875 | 1875 | mm |

Total weight (without stoker unit) | 585 | 865 | 865 | kg |

Safety heat exchanger | yes | yes | yes | |

Power supply | 400 V / 13 A | 400 V / 13 A | 400 V / 13 A |

|

* Combustion of P45A (G50) woodchips only in the case of excellent woodchip quality <br/> ** With auxiliary equipment; non-type-tested fuels. Possible use must be checked against country-specific and emission regulations.<br/> *** Output rating for Austria

Woodchips cost around half as much as oil. Furthermore, they are also an ecologically sound choice, as heating is provided in a way that is neutral to our climate, as only the same amount of CO2 is released by burning as was absorbed by the tree whilst it was growing. That is good for the environment – and good for our children.

Test report

Summary of test assessments:

"exceptionally high level of efficiency and fuel flexibility thanks to unique industrial step grate technology (even in the lower output range); minimum power consumption and highest operational reliability result from a clever discharge concept; ..."

- Tested for cleanest combustion and particularly high efficiency to EN 303-5 during 2005 and 2008 by the BLT Wieselburg and in 2006 by the TÜV BAYERN SZA

- Tested for mechanical robustness (under pressure) by the TÜV SÜD SZA

- Tested for fire safety by the IBS Linz

- Tested in accordance with the strict requirements of the European Machine and Plant Safety (CE)

- Tested for electrical safety by Ziviltechnik Stöp

- Assessment of risk analysis and CE certification by HET engineers

Awarded the Austrian Innovation Prize 2005

Awarded the Austrian Environmental seal ZU 37